Posts by Merav Burstein

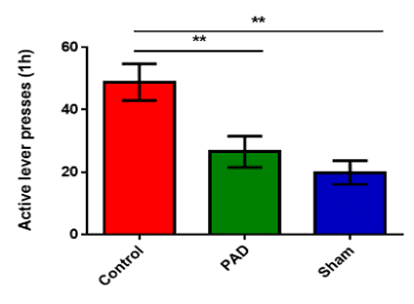

Pluri and Bar-Ilan University to Develop PLX Cells for the Treatment of Cocaine Addiction

HAIFA, Israel, December 21, 2023 – Pluri Inc. (Nasdaq: PLUR) (TASE: PLUR) (“Pluri” or the “Company”), a leading biotech company that transforms cells into solutions that promote well-being and sustainability, announced it has signed an agreement assigning the joint patent rights to develop Pluri’s PLX cells in the treatment of cocaine addiction, to BIRAD–Research &…

Read Moreחדשנות ויזמות על ציר אקדמיה -תעשיה

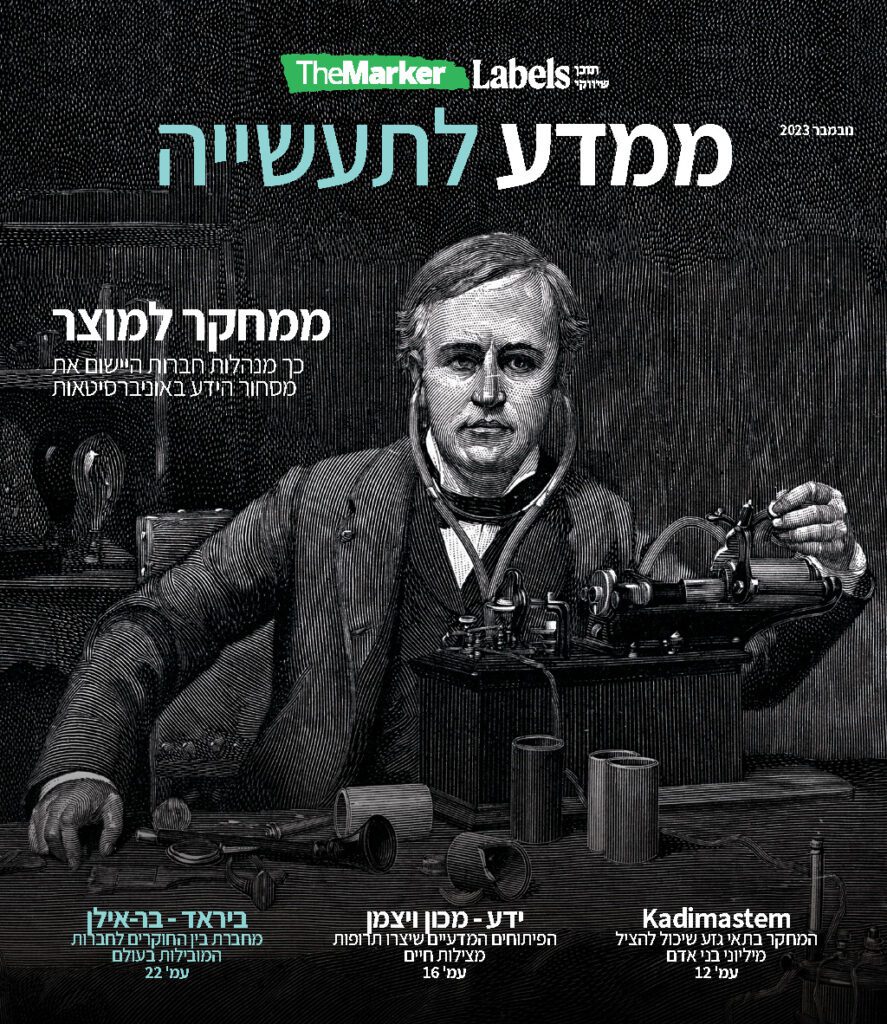

דה מרקר פרסם כתבה על היזמות והחדשנות שביראד מוביל באקדמיה הכתבה התפרסמה במוסף דה מרקר, והדגישה את החשיבות של שיתוף הפעולה בין אנשי הקדמיה לאנשי התעשייה. “המדענים באקדמיה זורעים את פירות העתיד הטכנולוגי”, אמר ד”ר צביקה בן פורת, מנכ”ל ביראד. בכתבה הוזכרו מחקריהם המתקדמים של פרופ’ דורון נווה, מהפקולטה להנדסה, פרופ’ דוד זיתון, ראש המחלקה…

Read Moreחוקרים בכירים מהארץ והעולם בשילוב נציגים מהתעשייה לקחו חלק ב כנס NLP ו Networks באוניברסיטת בר-אילן

חוקרים בכירים מהארץ והעולם בשילוב נציגים מהתעשייה לקחו חלק בכנס שהתמקד השנה בשני תחומי מחקר בולטים: Natural Language Processing – NLP ו Networks. הכנס נערך ביוזמה משותפת של ביראד חברה למחקר ופיתוח והמכון למדעי הנתונים באוניברסיטת בר-אילן, ובחסות החברות אורקל וגוגל. מעל 350 אנשי אקדמיה ותעשיה נחשפו להרצאות מרתקות ודיונים אינטראקטיביים שהתקיימו במליאה ואפשרו חשיפה…

Read MoreReducing CO2 in the Air

Prof. Doron Aurbach of the BIU Department of Chemistry Department and his team have developed an innovative system which efficiently absorbs CO2 from the air and converts it into fertilizer for growing vegetables The echoes of war have pushed climate change to the margins of the news, but the many hot days in November and…

Read MoreA New Milestone for Flexible Magnetic Sensors

A giant leap of more than an order of magnitude improvement in the sensitivity of flexible magneto-resistive sensors heralds new opportunities for flexible sensors in medical devices, soft robotics and more. Flexible magnetic sensors have gained popularity due to their versatility and potential applications in major areas of flexible electronics, including soft robotics, consumer electronics,…

Read MoreBar-Ilan University Hosts Conference for Managers of Scientific Infrastructure Centers in Israel

Significant Milestone Reached in Shaping the Future of Research Infrastructures Bar-Ilan University, Israel – Bar-Ilan University played host this week to the inaugural conference for managers of scientific infrastructure centers in Israel, marking a momentous occasion in advancing research infrastructures within the country. Organized by Bar-Ilan University’s Kanbar Center for Scientific Instrumentation, the conference gathered…

Read MoreHadassah Medical Organization and Bar-Ilan University Collaborate with Immix BioPharma for the Further Development and Commercialization of Next-Generation CAR-T Therapy

HBI0101, anti-BCMA CAR-T cells, showed 90% overall response rate in ongoing Phase 1b clinical trial with 50 relapsed/refractory multiple myeloma patients HBI0101 also demonstrated 100% overall response rate in 6 relapsed/refractory AL Amyloidosis patients Jerusalem & Ramat Gan, Israel – January 4, 2023 – Hadasit, the Innovation Engine of Hadassah Medical Organization and BIRAD, the…

Read MoreBar-Ilan Technology in Space

On April 6, the “Rakia” mission will head for space with technology to test vision in microgravity A digital vision test designed by Bar-Ilan University researchers Prof. Uri Polat and Prof. Yossi Mandel, together with Dr. Eran Schenker, Chief Medical Innovation Officer at the Israel Aerospace Medicine Institute, will be one of the scientific experiments…

Read MoreFuel Cells for Green Energy Production

A startup “born” in BIU’s Department of Chemistry offers clean and efficient solutions for energy production and storage without polluting emissions A new green-tech startup, Refhuel, will develop reversible fuel cell technology. The new company is the result of a partnership between BIRAD, Bar-Ilan Research & Development Company, and Refhuel Limited, a subsidiary of Decama…

Read MoreBIU, Doral Group Enter Strategic Collaboration

Bar-Ilan University and Doral Group, an entrepreneurial company in the field of renewable energy, have signed a series of agreements for strategic collaboration. Doral will become a member of Bar-Ilan’s Energy and Sustainability Center, and the entities will work to promote research, development, and commercialization of several issues, as well as identify and realize joint…

Read More